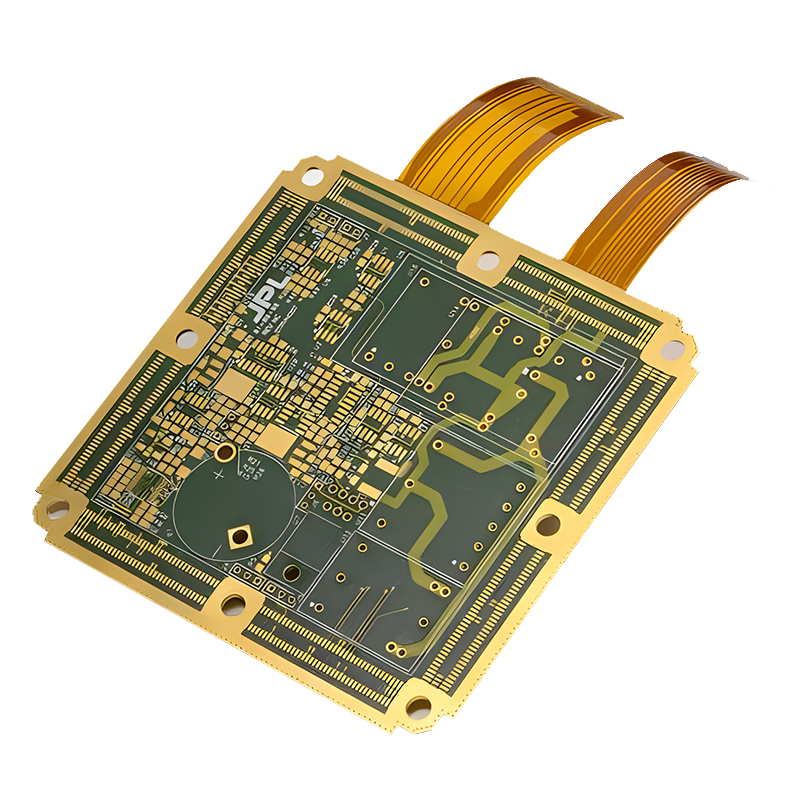

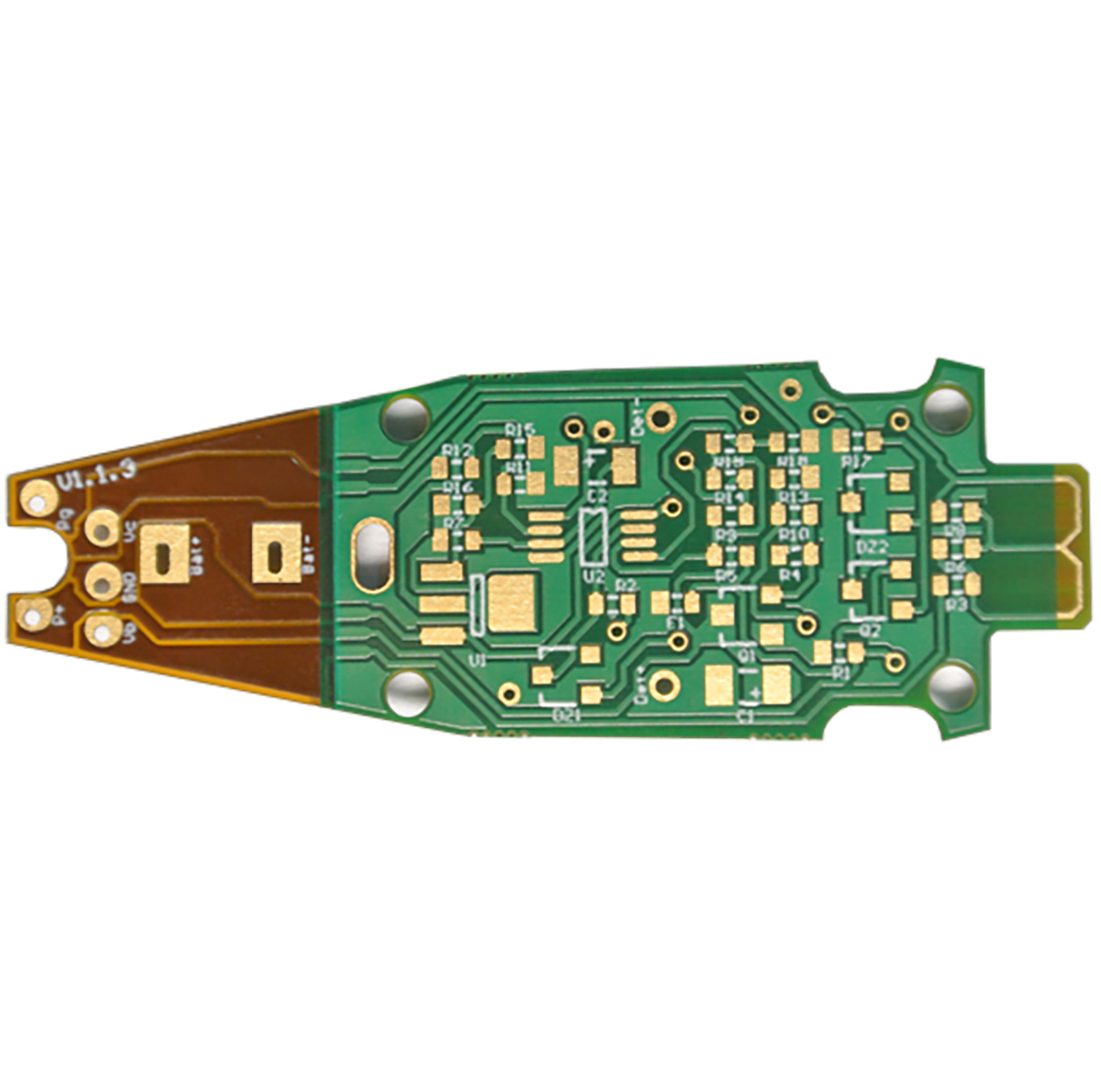

Rigid-Flex PCB consumer electronics PCB

Rigid-Flex PCB

Performance-wise, Rigid-Flex PCBs excel in applications demanding a combination of flexibility and structural integrity. The flexible portions allow the board to bend and fold, enabling intricate three-dimensional designs and conforming to the shape of the device. This flexibility reduces the need for additional connectors and wiring, enhancing reliability and reducing overall weight. The rigid sections provide stability and support for components that require a solid foundation.

The applications of Rigid-Flex PCBs are diverse and extend across industries such as aerospace, medical devices, and consumer electronics. Their unique design makes them ideal for devices where space optimization, weight reduction, and durability are critical factors. Common applications include wearable devices, aerospace instrumentation, and medical implants, where the combination of rigid and flexible elements accommodates the dynamic requirements of the application.

Interested?

Let us know more about your project.

REQUEST A QUOTE

PCB

PCB FPC

FPC Rigid-Flex

Rigid-Flex FR-4

FR-4 HDI PCB

HDI PCB Rogers High-Frequency Board

Rogers High-Frequency Board PTFE Teflon High-Frequency Board

PTFE Teflon High-Frequency Board Aluminum

Aluminum Copper Core

Copper Core PCB Assembly

PCB Assembly LED light PCBA

LED light PCBA Memory PCBA

Memory PCBA Power Supply PCBA

Power Supply PCBA New Energey PCBA

New Energey PCBA Communication PCBA

Communication PCBA Industrial Control PCBA

Industrial Control PCBA Medical Equipment PCBA

Medical Equipment PCBA PCBA Testing Service

PCBA Testing Service Certification Application

Certification Application RoHS Certification Application

RoHS Certification Application REACH Certification Application

REACH Certification Application CE Certification Application

CE Certification Application FCC Certification Application

FCC Certification Application CQC Certification Application

CQC Certification Application UL Certification Application

UL Certification Application Transformers

Transformers High Frequency Transformers

High Frequency Transformers Low Frequency Transformers

Low Frequency Transformers High Power Transformers

High Power Transformers Conversion Transformers

Conversion Transformers Sealed Transformers

Sealed Transformers Ring Transformers

Ring Transformers Inductors

Inductors Wires,Cables Customized

Wires,Cables Customized wires-cables

wires-cables