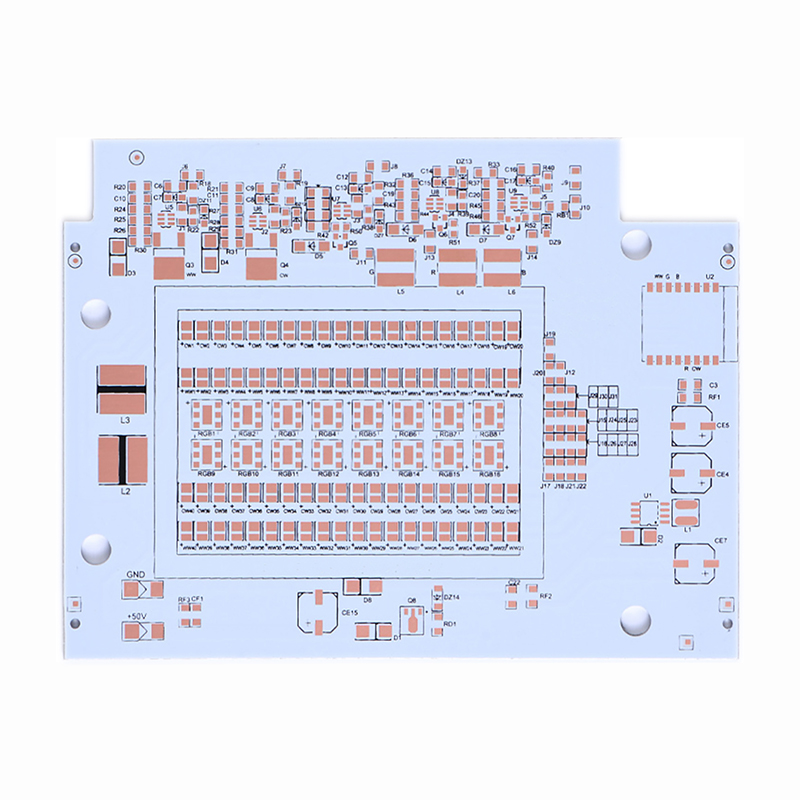

Aluminum PCB

The applications of Aluminum-Based PCBs are diverse, and they are commonly employed in industries requiring enhanced thermal performance. LED lighting fixtures, in particular, benefit from the superior heat dissipation capabilities of these boards, ensuring the longevity and stability of the lighting system. In automotive electronics, Aluminum-Based PCBs find application in power regulators, motor control units, and other components where temperature control is crucial.

The manufacturing process for Aluminum-Based PCBs involves laminating a thin layer of thermally conductive dielectric material onto the metal base. This dielectric layer provides electrical insulation while facilitating efficient heat transfer. PCB factories have developed specialized techniques to produce these boards efficiently, meeting the demand for thermal management solutions in various industries.

Interested?

Let us know more about your project.

REQUEST A QUOTE

PCB

PCB FPC

FPC Rigid-Flex

Rigid-Flex FR-4

FR-4 HDI PCB

HDI PCB Rogers High-Frequency Board

Rogers High-Frequency Board PTFE Teflon High-Frequency Board

PTFE Teflon High-Frequency Board Aluminum

Aluminum Copper Core

Copper Core PCB Assembly

PCB Assembly LED light PCBA

LED light PCBA Memory PCBA

Memory PCBA Power Supply PCBA

Power Supply PCBA New Energey PCBA

New Energey PCBA Communication PCBA

Communication PCBA Industrial Control PCBA

Industrial Control PCBA Medical Equipment PCBA

Medical Equipment PCBA PCBA Testing Service

PCBA Testing Service Certification Application

Certification Application RoHS Certification Application

RoHS Certification Application REACH Certification Application

REACH Certification Application CE Certification Application

CE Certification Application FCC Certification Application

FCC Certification Application CQC Certification Application

CQC Certification Application UL Certification Application

UL Certification Application Transformers

Transformers High Frequency Transformers

High Frequency Transformers Low Frequency Transformers

Low Frequency Transformers High Power Transformers

High Power Transformers Conversion Transformers

Conversion Transformers Sealed Transformers

Sealed Transformers Ring Transformers

Ring Transformers Inductors

Inductors Wires,Cables Customized

Wires,Cables Customized wires-cables

wires-cables