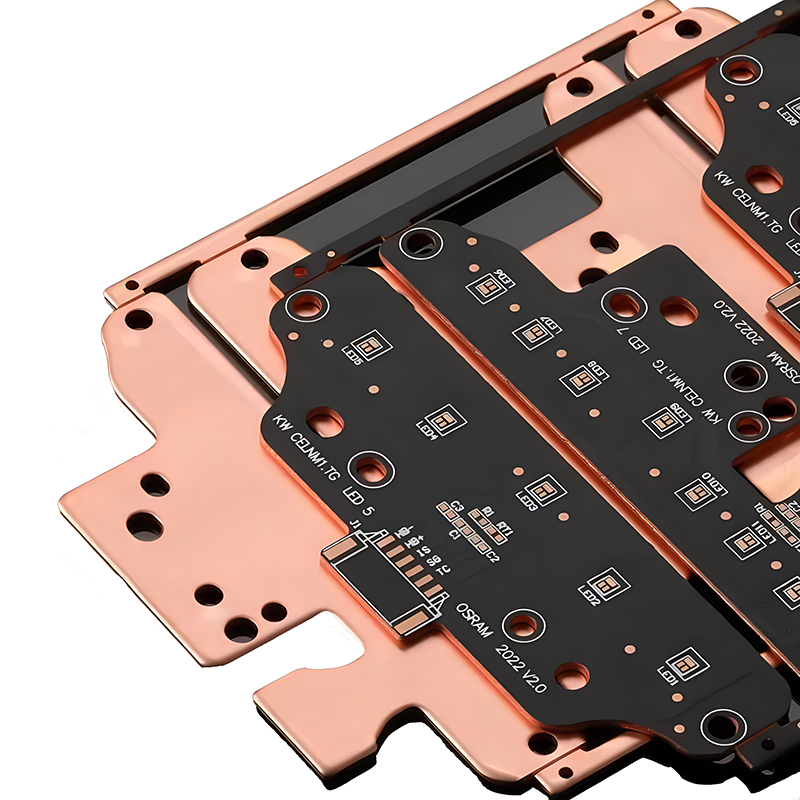

I-Copper Core PCB

Ukuhlelwa

Iipleyiti zesiseko sobhedu, njengezinto ezibalulekileyo kwishishini lokuvelisa i-elektroniki, zinokuhlelwa kwiindidi ezininzi ngokusekelwe kwisakhiwo kunye nokusetyenziswa kwazo. Iintlobo eziphambili ziquka:

Iibhodi zeSekethe eziprintiweyo zeMetal Core (MCPCBs): Ezi cwecwe zesiseko sobhedu zibonisa isiseko esenziwe kwisinyithi se-thermal conductivity ephezulu, njenge-aluminium okanye ubhedu, kunye neengqimba ze-foil zobhedu ekudalweni kweesekethe ezisetyenziselwa ukukhanyisa kwe-LED, abaguquli bamandla, kunye nezinye izicelo ezifuna ukutshatyalaliswa kokushisa okusebenzayo.

Amacwecwe esiseko seCeramic Copper: Ukusebenzisa izinto ze-ceramic njenge-insulating layer kunye ne-copper njenge-conductive layer, ezi zixhobo zesiseko zibonelela ngokugqithisileyo kokuxhathisa kwe-thermal kunye nokufakelwa kombane, ezifanelekileyo kwizixhobo ze-microwave, ukupakishwa kwe-semiconductor, kunye nezinye izicelo eziphezulu ze-frequency.

I-Thermoelectrically Sepasted Copper Base Plates: Ukubandakanya itekhnoloji ekhethekileyo yokwahlula i-thermoelectric, bagcina i-thermal conductivity egqwesileyo ngelixa bebonelela nge-insulation yombane, ilungele ulawulo lwe-thermal yezixhobo zombane.

Iinkqubo zokwenziwa kwemveliso

Iinkqubo zokwenza iipleyiti zesiseko sobhedu zibandakanya la manyathelo alandelayo:

Ukulungiswa kweSubstrate: Ukukhetha ikopolo ekumgangatho ophezulu okanye enye imathiriyeli efana nentsimbi okanye iiseramikhi njengesubstrate.

Ukulungiswa komphezulu: Unyango lwangaphambili lwe-substrate surface ngokucoca kunye ne-etching ukulungiselela ukunamathela okulandelayo kwe-foil yobhedu.

Ukudityaniswa kweFoil yeCopper: Ukufakela i-foil yobhedu kwi-substrate phantsi kweqondo lokushisa eliphezulu kunye noxinzelelo ukuze wenze i-conductive layer.

Ukugqithiswa kwePatheni kunye nokuTyelwa: Ukusebenzisa i-photolithography, i-laser, okanye ezinye iindlela zokudlulisa iipatheni zesekethe kwi-foil yobhedu kunye nokukhupha iikhemikhali kwiindawo ezingafunekiyo ukudala isiphaluka.

UkuQeda komphezulu kunye noKhuseleko: Ukusebenzisa unyango olungaphezulu olufana ne-tin plating, i-OSP (i-Organic Solderability Preservatives), i-ENIG (i-Electroless Nickel Immersion Gold), njl., ukunyusa iipropati ezichasene ne-oxidation kunye nokuthengiswa.

Iimpawu

Iimpawu eziphambili zeepleyiti zesiseko sobhedu ziquka:

High Thermal Conductivity: I-conductivity ephezulu ye-thermal yobhedu iyanciphisa ngokufanelekileyo ukushisa okusebenzayo kwizixhobo zombane, ukwandisa ubomi benkonzo.

Ukusebenza kakuhle koMbane: Ubhedu obucocekileyo buqinisekisa ukuchasana okuphantsi kunye nokudibanisa kombane okuzinzileyo.

Amandla oomatshini: I-Copper kunye ne-alloys yayo ibonisa amandla aphezulu, afanelekileyo kwiimfuno ezahlukeneyo zokucubungula kunye neendibano.

Ukunyangwa kokuMhlwa: Unyango olukhethekileyo lunika ukuxhathisa okulungileyo kwi-corrosion kumacwecwe esiseko sobhedu, okwenza ukusebenza kwiindawo ezinzima.

IiNdawo zokuSebenza

Iipleyiti zesiseko sobhedu zifumana ukusetyenziswa okubanzi kumacandelo amaninzi ngenxa yeepropathi zazo ezizodwa:

Ezobuchwephesha kunye nezoNxibelelwano: Kwiisekethe eziphezulu ze-frequency, izixhobo ze-microwave, iithegi ze-RFID, kunye nezinye iimveliso, iipleyiti zesiseko sobhedu zibonelela ngeendlela ezithembekileyo zokuhambisa umqondiso kunye nezisombululo zokutshatyalaliswa kobushushu.

I-Electronics yeemoto: Kwiinkqubo zokulawula iimoto, izibane ze-LED, kunye nezinye izicelo, ukusebenza kokushisa okuphezulu kokushisa kwamacwecwe esiseko sobhedu kwandisa uzinzo kunye nokhuseleko lwenkqubo.

I-Aerospace: Kwiisathelayithi, izixhobo ze-radar, kunye nezinye izixhobo ze-aerospace, ukuthembeka okuphezulu kunye nokukwazi ukumelana neemeko ezigqithisileyo zeepleyiti zesiseko sobhedu zibalulekile.

Amandla kunye nokuKhanya: Kwii-inverters zelanga, iinkqubo zokukhanyisa i-LED, kunye nezicelo ezifanayo, amandla okutshatyalaliswa kokushisa okusebenzayo kwamacwecwe esiseko sobhedu aqinisekisa ukuzinza kwenkqubo yexesha elide.

Unomdla?

Sazise ngakumbi ngeprojekthi yakho.

PCB

PCB FPC

FPC I-Rigid-Flex

I-Rigid-Flex FR-4

FR-4 HDI PCB

HDI PCB Ibhodi yeRogers High-Frequency

Ibhodi yeRogers High-Frequency Ibhodi ye-PTFE Teflon High-Frequency

Ibhodi ye-PTFE Teflon High-Frequency Aluminiyam

Aluminiyam ICopper Core

ICopper Core INdibano yePCB

INdibano yePCB Ukukhanya kwe-LED PCBA

Ukukhanya kwe-LED PCBA Imemori yePCBA

Imemori yePCBA Ubonelelo ngoMbane PCBA

Ubonelelo ngoMbane PCBA PCBA yaMandla amatsha

PCBA yaMandla amatsha Unxibelelwano PCBA

Unxibelelwano PCBA I-PCBA yoLawulo lwezoShishino

I-PCBA yoLawulo lwezoShishino Izixhobo zonyango PCBA

Izixhobo zonyango PCBA PCBA Testing Service

PCBA Testing Service Isicelo seSiqinisekiso

Isicelo seSiqinisekiso Isicelo seSiqinisekiso seRoHS

Isicelo seSiqinisekiso seRoHS FIKELELA kwiSicelo seSiqinisekiso

FIKELELA kwiSicelo seSiqinisekiso Isicelo seSiqinisekiso seCE

Isicelo seSiqinisekiso seCE Isicelo seSiqinisekiso seFCC

Isicelo seSiqinisekiso seFCC Isicelo seSiqinisekiso seCQC

Isicelo seSiqinisekiso seCQC Isicelo seSiqinisekiso se-UL

Isicelo seSiqinisekiso se-UL Transformers, Inductors

Transformers, Inductors High Frequency Transformers

High Frequency Transformers Iziguquli zeFrekhwensi ephantsi

Iziguquli zeFrekhwensi ephantsi High Power Transformers

High Power Transformers Conversion Transformers

Conversion Transformers Iinguqu ezitywiniweyo

Iinguqu ezitywiniweyo Ring Transformers

Ring Transformers Ii-inductors

Ii-inductors Iingcingo, iiCables ezenzelwe wena

Iingcingo, iiCables ezenzelwe wena Iintambo zeNethiwekhi

Iintambo zeNethiwekhi Iintambo zamandla

Iintambo zamandla Iintambo ze-antenna

Iintambo ze-antenna Iintambo zeCoaxial

Iintambo zeCoaxial Net Isikhundla Isalathisi

Net Isikhundla Isalathisi IiCapacitors

IiCapacitors Izihlanganisi

Izihlanganisi Iidiyodi

Iidiyodi Iiprosesa ezizinzisiweyo kunye nabalawuli

Iiprosesa ezizinzisiweyo kunye nabalawuli IiProsesa zeMiqondiso yeDijithali (DSP/DSC)

IiProsesa zeMiqondiso yeDijithali (DSP/DSC) Izilawuli ezincinci (MCU/MPU/SOC)

Izilawuli ezincinci (MCU/MPU/SOC) Isixhobo esinoLungiselelo lweNgqiqo(CPLD/FPGA)

Isixhobo esinoLungiselelo lweNgqiqo(CPLD/FPGA) IiModyuli zoNxibelelwano/IoT

IiModyuli zoNxibelelwano/IoT Abaxhathisi

Abaxhathisi NgeHole Resistors

NgeHole Resistors IiNethiwekhi ezixhathisayo, ii-Arrays

IiNethiwekhi ezixhathisayo, ii-Arrays Ii-potentiometers, ii-Variable Resistors

Ii-potentiometers, ii-Variable Resistors I-Aluminiyam Case, iPorcelain Tube Resistance

I-Aluminiyam Case, iPorcelain Tube Resistance IiResistors zangoku zeSense, Shunt Resistors

IiResistors zangoku zeSense, Shunt Resistors Iiswitshi

Iiswitshi Iitransistor

Iitransistor Iimodyuli zamandla

Iimodyuli zamandla Iimodyuli zamandla ezizimeleyo

Iimodyuli zamandla ezizimeleyo Imodyuli yeDC-AC(Inverter)

Imodyuli yeDC-AC(Inverter) RF kunye Wireless

RF kunye Wireless