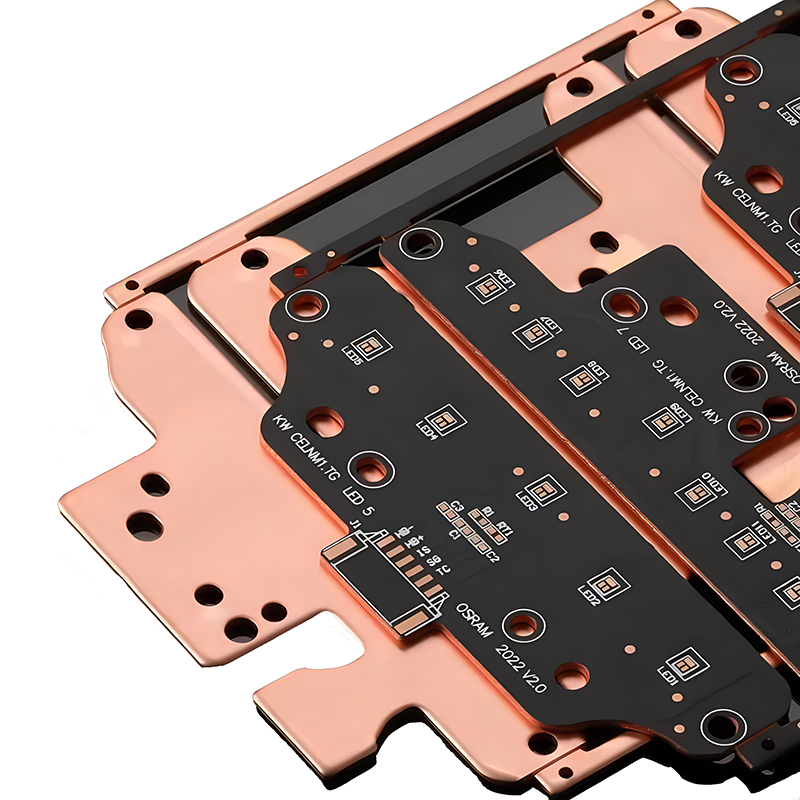

Mhangura Core PCB

Classification

Mhangura base mahwendefa, sechinhu chakakosha muindasitiri yekugadzira zvemagetsi, inogona kuiswa mumhando dzinoverengeka zvichienderana nechimiro uye mashandisiro awo. Zvikamu zvakakosha zvinosanganisira:

Metal Core Printed Circuit Boards (MCPCBs): Aya mahwendefa emhangura egasi ane musimboti wakagadzirwa kubva kune yakakwira thermal conductivity simbi, senge aruminiyamu kana mhangura, ine mhangura foil layers yekugadzira masekete anoshandiswa mukuvhenekesa kwe LED, magetsi anoshandura, uye mamwe maapplication anoda kunyatsoita kupisa.

Ceramic Copper Base Plates: Kushandisa ceramic zvinhu se insulating layer uye mhangura se conductive layer, idzi base plates dzinopa yakanyanyisa kupisa kupisa uye kuvharisa magetsi, inokodzera microwave zvishandiso, semiconductor packaging, uye mamwe ma-high-frequency application.

Thermoelectrically Separated Copper Base Plates: Kubatanidza tekinoroji yekuparadzanisa tekinoroji, ivo vanochengeta yakanakisa yekupisa conductivity uku vachipa magetsi ekudzivirira, akanakira epamusoro zvigadzirwa zvemagetsi 'thermal manejimendi.

Manufacturing Processs

Maitiro ekugadzira emhangura base maplate anowanzo sanganisira anotevera matanho:

Kugadzirira kwe Substrate: Kusarudza yemhando yepamusoro mhangura kana zvimwe zvinhu zvakaita sesimbi kana ceramics se substrate.

Kugadzirira Kwepamusoro: Pre-kurapwa kweiyo substrate pamusoro kuburikidza nekuchenesa uye etching kugadzirira kunotevera kunamatira kwefoiri yemhangura.

Kubatanidzwa kweCopper Foil: Kubatanidza foil yemhangura kune substrate pasi pekushisa kwepamusoro uye kumanikidzwa kuumba conductive layer.

Patani Kutamisa uye Etching: Kushandisa photolithography, lasers, kana dzimwe nzira kuendesa matunhu mapatani pafoiri yemhangura uye kemikari inobvisa nzvimbo dzisingadiwe kugadzira dunhu.

Surface Kupedzisa uye Dziviriro: Kuisa mishonga yepamusoro senge tin plating, OSP (Organic Solderability Preservatives), ENIG (Electroless Nickel Immersion Gold), nezvimwewo, kuwedzera anti-oxidation zvivakwa uye solderability.

Hunhu

Hunhu hwakakosha hwemhangura base mahwendefa anosanganisira:

High Thermal Conductivity: Iyo yakakwirira yekupisa conductivity yemhangura inobudirira inoderedza kupisa kwekushanda mumagetsi emagetsi, kuwedzera hupenyu hwebasa.

Yakanakisa Electrical Performance: High-purity mhangura inovimbisa kushomeka kushoma uye kugadzikana kwemagetsi kubatana.

Mechanical Simba: Mhangura uye alloys ayo anoratidza simba rakawanda, rakakodzera kune akasiyana siyana kugadzirisa uye gungano zvinodiwa.

Corrosion Resistance: Kurapa kwakasiyana-siyana kunopa kumira kwakanaka kwekuora kumahwendefa emhangura, zvichiita kuti kushanda munzvimbo dzakaoma.

Nzvimbo dzekushandisa

Copper base plates inowana yakakura kushanda muzvikamu zvakawanda nekuda kwezvakasiyana zvivakwa:

Electronics uye Telecommunication: Mumatunhu akakwirira-frequency, microwave zvishandiso, RFID tags, uye zvimwe zvigadzirwa, mahwendefa emhangura emhangura anopa nzira dzakavimbika dzekutumira zviratidzo uye zvigadziriso zvekupisa.

Automotive Electronics: Mumagetsi ekudzora masisitimu, mwenje we LED, uye mamwe maapplication, iyo yakanyanya kupisa kupisa kuita kwemhangura base maplateti inosimudzira sisitimu kugadzikana uye kuchengetedzeka.

Aerospace: Mumasetiraiti, midziyo yeradar, uye zvimwe zvigadziriso zvemuchadenga, kuvimbika kwepamusoro uye kugona kumirisana nemamiriro akanyanya ecopper base plate kwakakosha.

Simba uye Chiedza: Mune solar inverters, ma LED ekuvhenekesa masisitimu, uye maapplication akafanana, iyo inoshanda yekupisa kupisa kugona kwemhangura base maplate anovimbisa kugadzikana kwenguva refu kwehurongwa.

Kufarira?

Tizivise zvakawanda nezvechirongwa chako.

PCB

PCB FPC

FPC Rigid-Flex

Rigid-Flex FR-4

FR-4 HDI PCB

HDI PCB Rogers High-Frequency Board

Rogers High-Frequency Board PTFE Teflon High-Frequency Board

PTFE Teflon High-Frequency Board Aluminium

Aluminium Copper Core

Copper Core PCB Gungano

PCB Gungano Chiedza che LED PCBA

Chiedza che LED PCBA Memory PCBA

Memory PCBA Power Supply PCBA

Power Supply PCBA New Energy PCBA

New Energy PCBA Kukurukurirana PCBA

Kukurukurirana PCBA Industrial Control PCBA

Industrial Control PCBA Medical Equipment PCBA

Medical Equipment PCBA PCBA Testing Service

PCBA Testing Service Certification application

Certification application RoHS Certification application

RoHS Certification application REACH Certification application

REACH Certification application CE Certification application

CE Certification application FCC Certification application

FCC Certification application CQC Certification application

CQC Certification application UL Certification application

UL Certification application Transformers, Inductors

Transformers, Inductors High Frequency Transformers

High Frequency Transformers Low Frequency Transformers

Low Frequency Transformers High Power Transformers

High Power Transformers Shanduko Transformers

Shanduko Transformers Yakavharwa Transformers

Yakavharwa Transformers Ring Transformers

Ring Transformers Inductors

Inductors Waya, Matambo Akagadzirwa

Waya, Matambo Akagadzirwa Network Cables

Network Cables Power Cords

Power Cords Antenna Cables

Antenna Cables Coaxial Cables

Coaxial Cables Net Position Indicator

Net Position Indicator Capacitors

Capacitors Connectors

Connectors Diodes

Diodes Embedded processors & Controllers

Embedded processors & Controllers Digital Signal processors (DSP/DSC)

Digital Signal processors (DSP/DSC) Microcontrollers (MCU/MPU/SOC)

Microcontrollers (MCU/MPU/SOC) Programmable Logic Device(CPLD/FPGA)

Programmable Logic Device(CPLD/FPGA) Kukurukurirana Modules/IoT

Kukurukurirana Modules/IoT Resistors

Resistors Kuburikidza neHole Resistors

Kuburikidza neHole Resistors Resistor Networks, Arrays

Resistor Networks, Arrays Potentiometers, Variable Resistors

Potentiometers, Variable Resistors Aluminium Case, Porcelain Tube Resistance

Aluminium Case, Porcelain Tube Resistance Zvazvino Sense Resistors,Shunt Resistors

Zvazvino Sense Resistors,Shunt Resistors Swichi

Swichi Transistors

Transistors Power modules

Power modules Isolated Power Modules

Isolated Power Modules DC-AC Module(Inverter)

DC-AC Module(Inverter) RF uye Wireless

RF uye Wireless